Hose

Types, Designs & Approvals

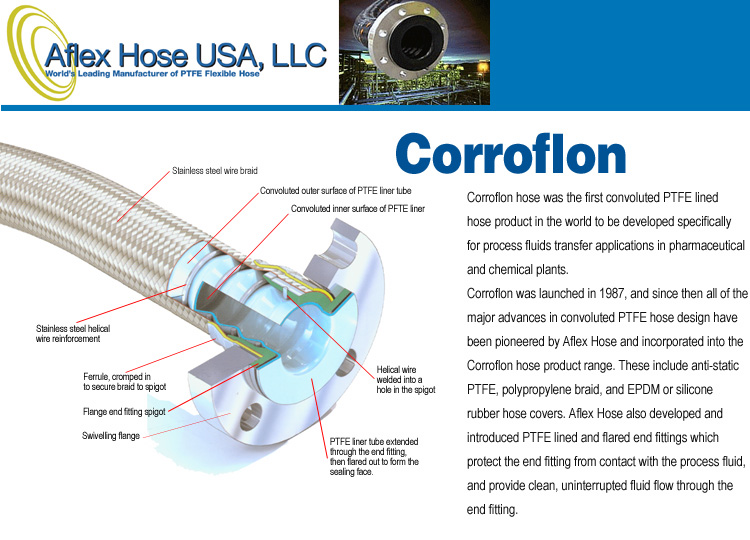

Over the years, Corroflon hose and end fittings have been continuously

developed and improved to maintain market leadership, and design

features which have been identified as prime requirements have

been incorporated at every stage.

These include

the thickest wall and the best processed tube lining available,

to prevent the development of porosity in the PTFE, which is the

primary cause of premature failure in competitors' products.

Corroflon is

also fully kink resistant and vacuum resistant due to the tight

helical wire reinforcement and the convoluted design profile.

The build quality

and design excellence of Corroflon hose have been tested and proved

in numerous applications worldwide, and hundreds of thousands of

Corroflon hoses have been applied and used successfully over the

last 30 years.

|

Advantages

over Conventional Hose

- Internally

"wetted" parts are all PTFE, protecting the end fitting from

any corrosive fluids.

- No bore restriction, so

fluid flow through the fitting is clean, without entrapment

zones.

- Corroflon will give better

clean ability and drain ability than other convoluted PTFE

hose on the market.

- Corroflon is the only

PTFE lined convoluted hose on the market to be fully kink

and vacuum resistant at high pressures and temperatures.

- Aflex is the only PTFE

hose manufacturer to guarantee a minimum PTFE liner thickness

of 1.5mm for hose sizes 1" and above. Which ensures sufficient

strength to prevent the tube from being internally pressurized

from a sine wave shape into an extended square wave shape.

which would lead to porosity and eventually premature failure

of the tube.

|

|

Specifications: |

|

|

Tubing |

|

Convoluted,

Reinforced PTFE Lined Hose |

Material of Construction |

|

PTFE lined hose |

Size Range ID

(in.) |

|

0.500" up

to 6" |

Maximum

Operating Temp. (internal fluid) |

|

SS Braid -95°F

to - +445°F, PB Braid -22°F through +212°F |

Pressure

vs Temperature |

|

PAll sized of

Corroflon, up to 2" bore are usable at full vacuum up to 265°F.

At higher temperatures, the vacuum resistance should be reduced

1% for every degree above 265°F. For sizes above 2" bore, the

vacuum resistance depends on the bend radius used. In general,

for sizes above 2" when high/full vacuum resistance is required,

use SP grade. |

USP Class VI

Approval |

|

Yes |

Hose

Design Options |

|

Natural or anti-static

PTFE, stainless steel braid, with or without an EPDM or silicone

rubber cover or polypropylene, PVDF or hastelloy braid. |

End

Fitting Options

|

|

SASA 150 or DIN

flanges, Sanitary Triclamps (Triclover), Camlocks, DIN 11851,

RJT, SMS, RJP fittings, BSPT or NPT fixed males, BSP or NPSM

females, JIC, I-Line and many others standard and special fitting

designs. |

|

|

|

For

more information

about Corroflon

just click on the graphic

to the right to open an

Adobe Acrobat PDF file.

|

|

|

|

|